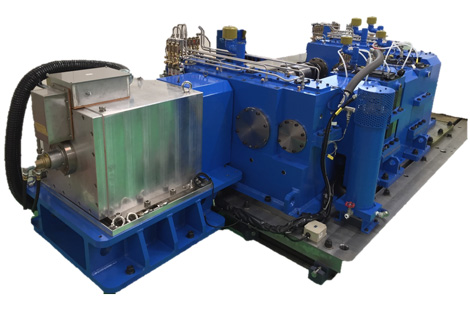

Transmission Dynamo Tester

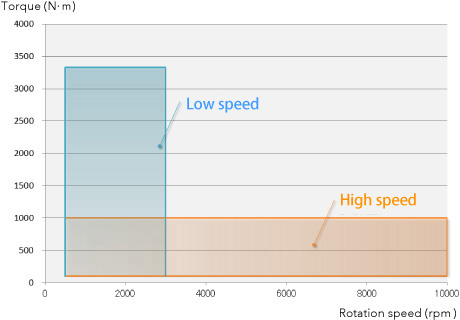

- High-speed response and low noise level by low inertia dynamometer.

- Transmission efficiency that has a direct link to fuel economy can be measured

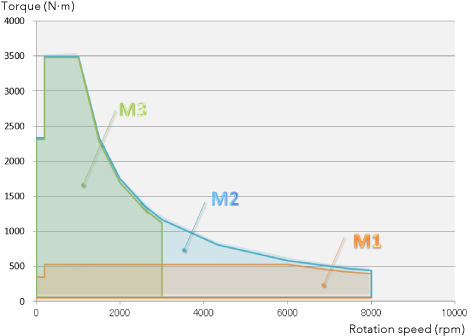

- Variable 3-axis system can support various types of function tests for FF, FR and differential gears